Next summer, the University of Wisconsin will be home to a new instrument worth $1.1 million.

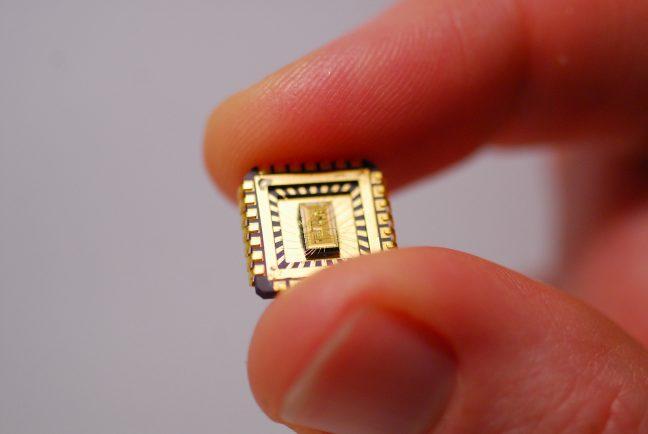

Capable of creating extremely fine patterns at the nanometer scale with research applications from physics and chemistry to biology and medicine, it’s no wonder the electron beam lithography system carries such a hefty price tag.

The new tool, which can make structures to about seven nanometers, will provide UW and the entire state of Wisconsin with state-of-the-art nanofabrication capability, engineering professor Mikhail Kats said in an email to The Badger Herald.

The instrument is set to become a part of the shared facilities at UW, Kats said, and will be included as a learning tool in an Advanced Laboratory course in the Physics department and a Fabrication Laboratory course in the chemical engineering department.

Purchase of the EBL system was made available through a recent grant of $799,996 awarded to the university by the National Science Foundation. Contributions from UW itself, including support from the Wisconsin Alumni Foundation, are earmarked to cover the remaining cost.

Materials science professor Mike Arnold said while lithography, which is essentially a form of printing, is used in a variety of fields, it’s most predominantly used in the electronics industry.

In the electronics industry, it’s used to create patterns on the surface of silicon wafers. To do this, a researcher takes the material he or she wants to create a pattern on, in this case a semiconductor, and coats it in a thin layer of film. A lithography system is then used to project light onto the film. Dissolving film wherever it’s projected, the light produces the desired pattern, leaving film behind to create something of a stencil. This resulting stencil dictates the exact shape of the metal subsequently applied to the original material.

Currently, Arnold said, many of the lithography systems available for use around Wisconsin use light waves to dissolve that first layer of film. This means that the level of precision of these systems is restricted by the preciseness of the width of a lightwave. A wave of light can only be so narrow, Arnold said.

There are scanning electron microscopes that attempt to convert the light to enable electron beam writing, but they lack the level of precision the EBL system will reach.

In contrast, the EBL system projects electrons individually, giving it nanolevel of precision — as precise as the width of a single electron.

The capability to create patterns at the nanoscale shrinks the distance between electrodes, Arnold said, and the distance between electrodes affects how fast the chargers go.

“The smaller you can make a transistor, the better the transistors will be,” Arnold said.

For his own research, Arnold said he intends to deviate from silicon wafers and use the EBL system to create patterns on carbon materials in the hopes of creating carbon transistors.

UW physics professor Mark Eriksson, who led the grant application for the system, said the instrument will not only support the research of professors across disciplines, but makes research more efficient for graduate students.

“I think the most exciting thing is it’s a very useful tool for graduate students and the work they’re doing,” Eriksson said.