A team of engineers at University of Wisconsin have developed a functional and flexible transistor to render electronic gadgets that are faster, simpler and more cost effective.

The team consists of leading engineering professor Jack Ma, Jung-Hun Seo of the University at Buffalo, State University of New York; Kan Zhang of UW; and Weidong Zhou of the University of Texas at Arlington.

Transistors, Ma said are an essential element of circuiting, which are the base of all electronic gadgets.

There are analog circuits and digital circuits. Analog circuits help to amplify signals, Ma said. Digital circuits are utilized for logic and computation.

Ma said when analog and digital are used simultaneously in one system the system is called a mixed-signal system. Today it is commonly used in most gadgets such as cell phones and DVD players.

Bipolar transistors are used for analog systems and complementary metal-oxide is used for digital, Ma said.

Transistors have been mechanically flexible since about 2006. But, flexible analog and digital transistors were always made separately, Ma said.

It was not until the two semiconductor technologies were integrated that a high speed and flexible platform proved more auspicious than two separate semiconductor technologies, Ma said.

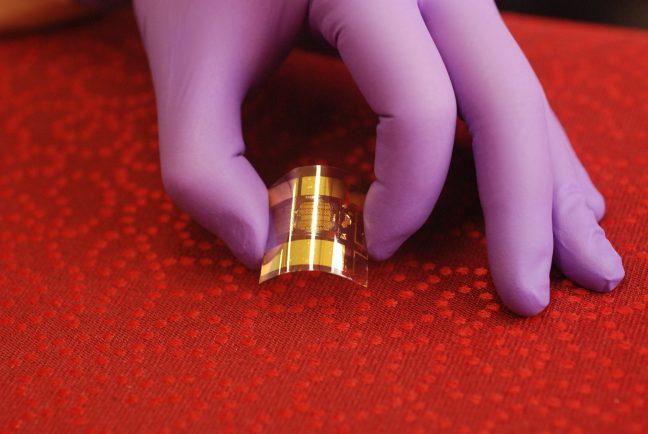

The new integrated platform is called the Bipolar Complementary Metal Oxide Semiconductor, Ma said. Flexible electronic transistors of this quality had not existed before the work done by Ma and his team.

“The method for producing this platform is both cost-effective and timely and our flexible transistors hold the record speed,” Ma said.

This new technology can be useful in many types of gadgets such as wearable electronics. The dilemma comes when mechanical flexibility is needed to enhance performance, structure and capability, Ma said.

The process for creating traditional BiCMOS and rigid technologies is difficult, Ma said. The several high-temperature steps and extreme precision needed to fabricate the transistor causes the process to take considerable time.

“Traditional rigid electronics need three months to finish,” Ma said.

Ma and his team accomplished this fabrication process in a week. Their method eliminates many of the steps needed for creating traditional rigid technologies. This decreased both the time and cost to fabricate the new BiCMOS transistor by a considerable amount, Ma said.

Renee Meiller, Director of Communications for the College of Engineering at UW, said this kind of innovation is something that is very integral to UW and the College of Engineering’s research mission as a whole.

With Ma as a “world leader” in his field, Meiller believes this advancement in transistor and BiCMOS technology will have an immense effect on new and existing products.

“This advancement is an outstanding example of the world-leading research conducted in the College of Engineering,” Meiller said. “Not only will it improve existing products and enable new ones, it exemplifies the principles and traditions of the Wisconsin Idea.”