A team of University of Wisconsin engineering students are working to break barriers to allow for wheelchair accessibility in the gym. The students are redesigning the rowing machine, a fitness device, so those in wheelchairs can utilize the machine as well.

But, instead of making separate machines, they are working toward a dual machine that can be rotated between standard users and wheelchair users alike, according to the College of Engineering.

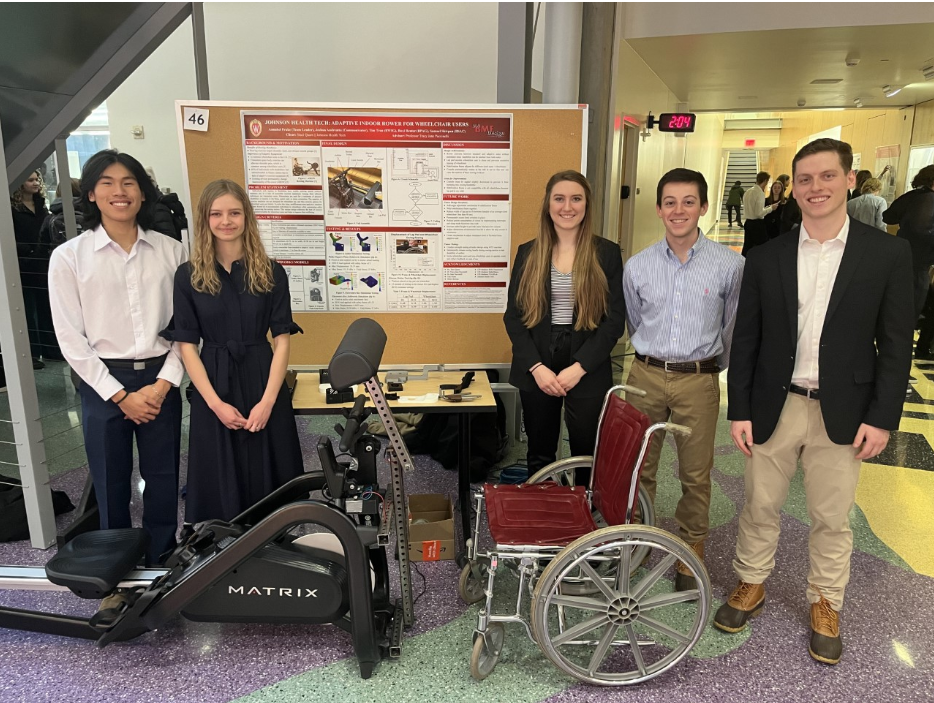

The team is made up of five biomedical engineering students — Tim Tran, Annabel Frake, Roxi Reuter, Josh Andreatta and Sam Skirpan.

This design initiative is the students’ senior capstone project. At the beginning of biomedical engineering students’ senior year, they must choose a project from a list of design ideas from clients and apply for one. Skirpan said after their team was accepted into the rowing machine project, they met with the client to hear the design pitch. The client, Johnson Health Tech, came in with a rowing machine and asked if they could adapt it for wheelchair use.

“One of the big things that is unique between our project, in our design, compared to other designs that allow for wheelchair users, is that it retains the functionality of a traditional rower to use it from a standard side but also allows for someone who requires a wheelchair to use it on the adaptive side,” Skirpan said.

A rowing machine is an exercise machine commonly found at most gyms. According to Mayo Clinic, they normally consist of a seat, a handlebar, foot pedals, a tracking console and a flywheel, which moves the pulley system.

A user will sit in the seat and reach to grab the handlebar with both hands. Their arms should be in a straight line at their chest as they pull the handlebar toward them. In some machines, the seat is non-moving, while some seats slide with the user, according to Mayo Clinic.

Skirpan said the team’s client and fitness manufacturer, Johnson Health Tech, has machines that can adapt to a wheelchair already. But, they can’t be converted from a standard machine to an adapted machine. The team has been designing a prototype that will allow the rowing machine to be convertible rather than a separate machine.

Andreatta said his team kept the seat from the original machine on one side but made the machine itself double-sided. One side is designed for standard use. On the other side, there is a rollercoaster-like lap bar for wheelchair users to strap into the rowing machine.

Frake primarily focuses on the project’s electronics. Frake said in order for the rowing machine to be usable on both sides, shared parts must be able to rotate back and forth. The team is currently working on designing the data console to turn from one side to the other automatically. This gives both users the opportunity to track their progress.

Frake said rowing machine users can choose different resistance levels to make the workout more or less intense. The team is currently working to alter the machine, so both users can change the resistance level on their side.

“We opened up the mechanics of the inside of the machine and altered them using a separate motor and some more electronics so that we could try to hijack the system [and] so that we can alter that [resistance level] from both sides of the machine,” Frake said.

Andreatta said there are two main parts of the project design — modeling and electronics. The first step is modeling. Reuter is the team’s main sketcher, incorporating her interests in art by using sketches to help design abstract ideas into models.

Andreatta said to start the modeling process, Reuter usually sketches out their ideas to visualize the concepts. There may be multiple sketches and many changes throughout the process. When the team is satisfied with the sketches, they move on to 3D models.

The team used a computer-aided program to make 3D models of their original sketches. Once satisfied with the computer models, they use 3D printers to print physical models and test whether the modifications will actually fit on the rowing machine, according to Andreatta. Trial and error is a significant aspect of the process.

Frake said the concept of modeling is the same for the electronics aspect of the prototype. But, electronics starts with abstract coding. Frake tests ideas with the coding system to figure out what exactly they want the program to do.

Once they figure out the exact instructions, the team makes a schematic — a pictorial guide indicating how to put the components together, Frake said. This is used to assist in making prototype circuits. Once the design is perfected, a project member solders the electric wires together.

While some of the team members have specific roles like communications, electronics or modeling, Andreatta said all of the members contribute equally across the board. The team has been able to develop their individual skills to create an innovative design that can be used to improve others’ lives. Communication, teamwork and collaboration are just some of the skills these students can take to their future careers.

The team will present a demo of this machine Friday, April 28, from 12-2 p.m. in the atrium of the Engineering Centers Building at UW.