When Mike Grosskreutz started working at the Wisconsin Rapids paper mill in 1980, he thought his job would last until retirement. After all, the paper mill was the place everyone in the area wanted to work. Forty years later, Verso, the then owner of the Wisconsin Rapids paper mill, announced their plan to shut down the mill in June 2020.

“Morale dropped quite a bit,” Grosskreutz said. “Kind of like you’ve pulled the rug out from everybody’s feet. And nobody knew what to think or do or say.”

Verso said the decision to close the mill stemmed from COVID-19 pandemic, which caused a sharp decline in demand for the glossy magazine paper Wisconsin Rapids mill produced.

The Wisconsin Rapids mill was one of the last paper mills in the state to produce magazine paper, though Wisconsin Paper Council Executive Director Scott Suder said the paper industry is more than just printing paper. Wisconsin’s paper mills produce tissue products like toilet paper and napkins, specialty paper products used in food packaging, cardboard box material and more.

“You know, paper is not just what people might think of, just white paper,” Suder said. “Fiber and paper making is in almost every aspect of our lives. Not just paper toweling, but it’s in aerospace. It’s in your car, it’s in your phone, it’s in your clothing.”

Wisconsin’s paper industry is as old as the state itself, with Wisconsin’s first paper mill starting production in 1848. Wisconsin leads the nation in the number of paper mills, number of paper industry employees and amount of paper sold, according to a 2019 report from the Wisconsin Paper Council.

Wisconsin’s paper industry generates about $18 billion and employs over 30,000 people, making it the fifth-largest manufacturing sector in the state. At the time of the report, Wisconsin had 34 paper mills. There are now 32, according to Suder.

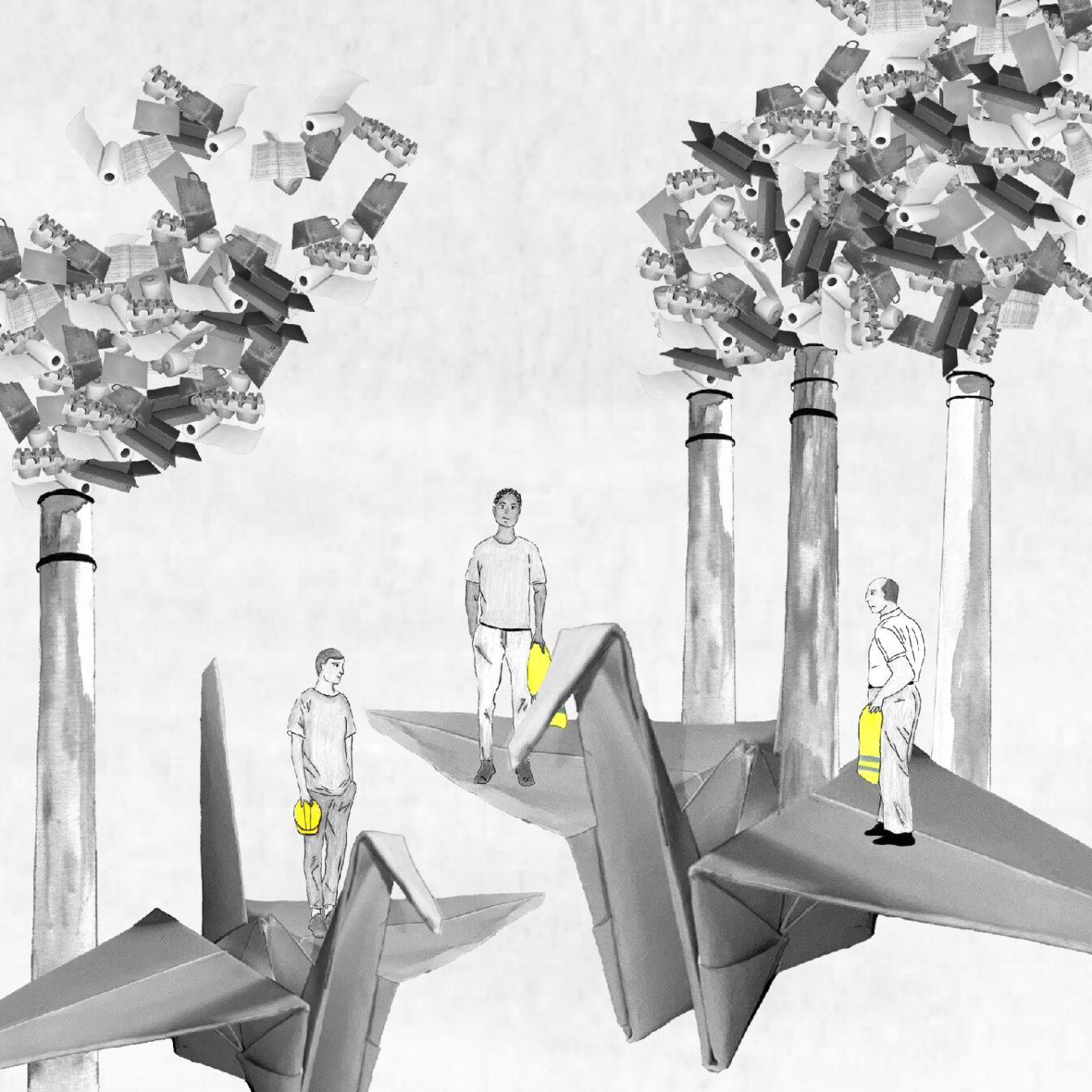

Wisconsin’s paper industry has grappled with shifting consumer demands and transitions in company ownership for the last few decades. While some paper mills have evolved to meet these new demands, others don’t receive the investment they need from their owners, leading to shutdowns, lost jobs and detrimental impacts on communities across the state.

Shredding an industry

Wisconsin Rapids is one of the latest mill closures in Wisconsin’s paper industry. In the past three decades, at least a dozen paper mills closed with many sitting empty, undergoing redevelopment or being sold for parts.

The reasons Verso gave for the shutdown didn’t satisfy the 900 employees who lost their jobs, Wisconsin Rapids Mayor Shane Blaser said.

“There’s lots of ‘Why here? Why now?’” Blaser said, “You know, what’s wrong with our mill? Why, isn’t it marketable? Why isn’t another company interested in buying it? What’s wrong with it? What’s it going to take? You know all those questions are kind of up flurrying around.”

Other industries have expanded into Wisconsin Rapids, and people found new jobs at those companies or other nearby paper mills, Blaser said. While there is no tracking mechanism for where the employees ended up, Blaser estimates that about one third of the employees retired following the announcement.

Tim Pavlik is the president of United Steel Workers Local 2-94, the union that represented the Wisconsin Rapids paper mill workers. After the initial shock wore off, he worked with other local leaders to help the employees find other employment opportunities through job fairs and career assistance programs.

“From when they announced in June till the mill shut down in August, we had a very, very short time period,” Pavlik said.

Two years later, things have settled down in Wisconsin Rapids. But, the city’s economy still feels some of the effects. The shutdown lowered the city’s median income, Blaser said, making Wisconsin Rapids a less attractive location to retail outlets that are looking to expand in the area. Residents drive to nearby Plover to shop, but many want to see more retail in their own city.

The mill closures in Wisconsin Rapids are not an isolated incident. In the late 2000s, many paper industry employees came to University of Wisconsin-Oshkosh director of customized research and services Jeffery Sachse with their concerns about the paper industry when he worked for the Wisconsin Department of Workforce Development. At the time, paper companies had started shutting down smaller paper mills and moving their production to larger facilities.

Like Wisconsin Rapids, paper mills can close due to a decline in demand for the type of paper they produce. But economic incentives and a lack of connection between out-of-state companies and the communities who run the paper mills has also led to paper mills closing across that state.

In the 1970s, privately owned paper companies started turning to private equity firms for money to invest into their paper mills, Sachse said. Because of this change, the families and individuals who actually ran the paper mills gave up their position as the company’s main decision maker. The new leadership often chose to restructure the company.

These changes often took the form of bankruptcy proceedings and merging companies under new ownership. As a result, a lot of paper industry leadership left the state. This change then opened up Wisconsin’s paper industry to management decisions made by people who don’t live and work in Wisconsin, Sachse said.

Before out-of-state companies and private equity firms owned many of Wisconsin’s paper mills, most were run by families and companies based in the same community. In Wisconsin Rapids, the Mead family owned the paper mill for most of its history. When there were no family members left to take over, they sold the company and its paper mills.

“It kind of had this aura about it and the history and the community but that all changed once it became no longer locally owned, and it just became a business and a balance sheet for somebody,” Blaser said.

Before paper, there is pulp

Industries and communities outside of Wisconsin Rapids felt the effects of shutdown too — one such industry being pulp production. The Wisconsin Rapids paper mill was the state’s largest consumer of pulpwood, which come from trees that don’t meet the quality standards for lumber and are instead used to make paper. Pulpwood is broken down into wood fibers — pulp — then reformed to create paper products.

When the mill closed, professional loggers in Wisconsin’s northwoods didn’t have a place to sell their pulpwood.

The day Verso announced they were shutting down the Wisconsin Rapids paper mill, Dennis Schoeneck had five trucks of freshly-cut wood ready to head for Wisconsin Rapids. Then, a friend who worked in the logging industry advised him to call Verso. When he did, a mill employee told Schoeneck that as of 4 p.m. that day, the paper mill was no longer accepting wood shipments.

“I sent two of our trucks down there and that was it,” Schoeneck said. “So I didn’t get … a month, I literally got four hours. Talk about a shock to a system.”

When the mill closed, there was a flood of pulpwood on the market, which caused the price to drop, Schoeneck said. Many Wisconsin loggers went out of business, but Schoeneck managed to hang on. While his logging business generates enough revenue to make a living, there isn’t enough income to invest in new equipment.

When loggers struggle, forest health struggles too. UW professor and wood products specialist Scott Bowe said loggers play an important role in managing the state’s private and government owned forests.

To manage a forest correctly, loggers can’t go in and only take the valuable wood that goes into lumber. Loggers must take the pulpwood and there needs to be a market for it, Bowe said. When some northeastern states lost portions of their paper industry, it impacted the management of their forests because there was nowhere to sell the timber once it was harvested.

A managed forest has younger, healthier trees, stores more carbon and experiences less disease, Bowe said. People see the deforestation happening down in South America and assume loggers do the same in Wisconsin, but the state is actually gaining forest land.

“So, in Wisconsin we talk about healthy forests depending upon a healthy forest products industry,” Bowe said. “So, if we don’t have an industry that wants to use those raw materials, we have no financial incentive to manage our forest.”

Repackaging the narrative

Though some say the paper industry is declining in Wisconsin, Suder said the paper industry is far from dead. While Wisconsin lost several paper mills in the past decade, the industry has diversified and companies have become more specialized. So, while the industry has consolidated, production in Wisconsin’s paper mills is going strong.

Suder pointed to Green Bay Packaging as an example of growth in Wisconsin’s paper industry. In 2021, the company began production on their new $500 million paper mill. The mill holds the first new paper machine the state has seen in over 35 years.

The new Green Bay Packaging paper mill was designed to be more environmentally friendly than a traditional paper mill, which uses a lot of water and energy. The new paper mill has a net zero water certification and uses more recycled material in their production process. The company also switched from coal boilers to natural gas, which cuts down on sulfur dioxide and nitrogen oxide emissions.

Unlike Verso, Green Bay Packaging is based in Wisconsin and operates paper mills locally. While the Wisconsin Rapids mill made magazine paper, Green Bay Packaging makes the material used in cardboard boxes.

Green Bay Packaging’s new mill is part of an emerging generation that produces different products than traditional magazine and printing paper. The industry is evolving toward more specialty papers, such as food packaging, labels and materials used in corrugated boxes. In fact, Wisconsin is Amazon’s number one producer of cardboard boxing materials, Sachse said.

But even if older paper mills want to get into the packaging and cardboard market, they can’t simply transition from producing white or magazine paper to specialty papers and containerboard, Sachse said. Without companies making a large investment, older mills don’t have the right equipment that would allow them to move into more lucrative paper markets.

While paper mills produce different products today, they also look remarkably different than they did 30 years ago. Mills are undergoing the process of automation, with much of the equipment becoming digitized over the past several years. Anyone walking through a modern paper mill will see very few people on the floor with the machines and more people monitoring operations in windowed offices, Sachse said.

There is a strong demand in the industry for technically skilled workers — one that is not being met. With the loss of the traditional aspect and the effects of an aging workforce, the industry struggles to efficiently replace outgoing employees.

UW-Stevens Point associate professor Roland Gong said mills are now looking to fill these positions with engineers. Though most of his paper science and chemical engineering program’s graduates end up with high paying jobs in the paper industry in Wisconsin, it is still in need.

The ‘Mill Bill’

Constant shutdowns and ownership changes take a toll on people who work in the paper industry. The Great Lakes Timber Professionals Association was one group who wanted to take matters into their own hands — they decided to form a co-op after the Wisconsin Rapids mill shutdown.

Forestry professionals watched for years as different entities came in and purchased paper mills. These companies didn’t reinvest in the paper mills and instead sold them off a few years later, Great Lakes Timber Professionals Association executive director Henry Schienebeck said. These constant changes affected loggers across the Great Lakes region.

Schienebeck wanted the loggers and the community to control their own destiny. For a couple years before the Wisconsin Rapids paper mill shut down, they discussed the idea of forming a co-op. They thought if they owned and got the community involved in managing the paper mill, they could run it more efficiently, Schienebeck said.

“If you’re an owner of something, you take better care of it, right?” Schienebeck said. “If you had to earn it … you just do all these things that make it more cost-effective to run. That’s the model we were using, and still are using.”

The Great Lakes Timber Professionals Association partnered with local representatives to find financial resources for the co-op to buy the paper mill. This “mill bill” would have provided the co-op with funds to start the process of buying the mill.

While both the state Democrats and Republicans wanted to pass the bill, it quickly became a partisan showdown over where to obtain the funding. Republicans wanted the money to come from the American Rescue Plan Act funds, which were designed to help businesses affected by COVID-19. Democratic Gov. Tony Evers wanted to use the state’s general purpose revenue funding.

The “mill bill” passed the state Legislature, but it never went into effect because Evers vetoed it. Evers said that American Rescue Plan Act funds are not suitable for the long term investment the project needed. He also cited legal problems that could arise if the federal government didn’t think COVID-19 directly caused the mill closure.

After Verso closed the Wisconsin Rapids mill in 2020, the company merged with BillerudKorsnäs AB, a Swedish paper company. The Swedish company is currently running its paper mills in Escanaba and Quinnesec, Michigan, with no apparent plans for the Wisconsin Rapids paper mill.

Wisconsin Rapids hired a company to do a redevelopment study using a federal grant, Blaser said. The report isn’t finished yet, but it will include some options for redevelopment of the mill property now that the mill is no longer running.

Grosskreutz said there was hope that someone would buy the Wisconsin Rapids paper mill for a couple years, but now too much time has passed. The machines will no longer run correctly after sitting idle for so long.

Grosskreutz got his full retirement, but he took a job operating a dump truck in the summer for a landscaping company and became an ordained minister.

Despite all the changes, Pavlik believes there are still opportunities in Wisconsin’s paper industry.

“The paper industry has opportunities,” Pavlik said. “I believe that. I [also] believe that it’s a different industry than it was when I got into it 27 years ago. My father was a 48 year employee at Consolidated Paper and it was different when he got into it. So I think it’s continuing to be a strong part of Wisconsin’s economy going forward.”